DynaSeal™ Benefits DynaSeal™ Standard Specifications: ≥ 15” Hg Vacuum; 60-120˚F Ambient Temperatures; 180˚F Inlet Gas Temperature Max; 180˚F Discharge Gas/Oil Temperature; If conditions differ, consult factory for recommended design modifications.

200˚F Inlet Gas – Consult factory.

Capacity Range Standards 15-1000 ACFM. Larger systems available upon request.

Low Noise Level. Unlike rotary screw vacuum pumps, which run at rotor speeds as high as 9000-rpm, DynaSeal™ systems operate at conservative speeds (1750-rpm) resulting in low noise levels (75-80 dBA at 3-ft.) acceptable to the environment without the need for sound enclosures.

Minimal Maintenance. DynaSeal™ systems typically only require an oil change and replacement of discharge filter every 10,000 hours under normal operating conditions. No other maintenance is required except for periodic greasing of bearings.

Not affected by carry-over of soft solids or liquids. DynaSeal™ systems can handle carry-over of soft solids and liquids without damage to the system components. We do however recommend to install an inlet filter/strainer or knock-out pot in those applications where a high carry-over of either solids or liquids is expected. Designed for continuous operation.

Continuous Operation DynaSeal™ systems are designed for continuous operation over the full vacuum range without overheating.

Automatic Temperature Control. Prevents low temperature operation, reduces accumulation of water and other liquids in the reservoir and decreases the risk of bacteria growth. This optional feature is very important in hospital and other intermittent duty applications.

Low Vibration. DynaSeal™ systems require no special foundations or anti-vibration mountings as a standard.

High-Quality Manufacturing Standards. Travaini pumps are manufactured under ISO 9001 quality control standards.

Quality Control DynaSeal™ systems are a “proven design”. Combine this with our inline quality procedures and outgoing inspection, this provides you with the leading quality in the industry.

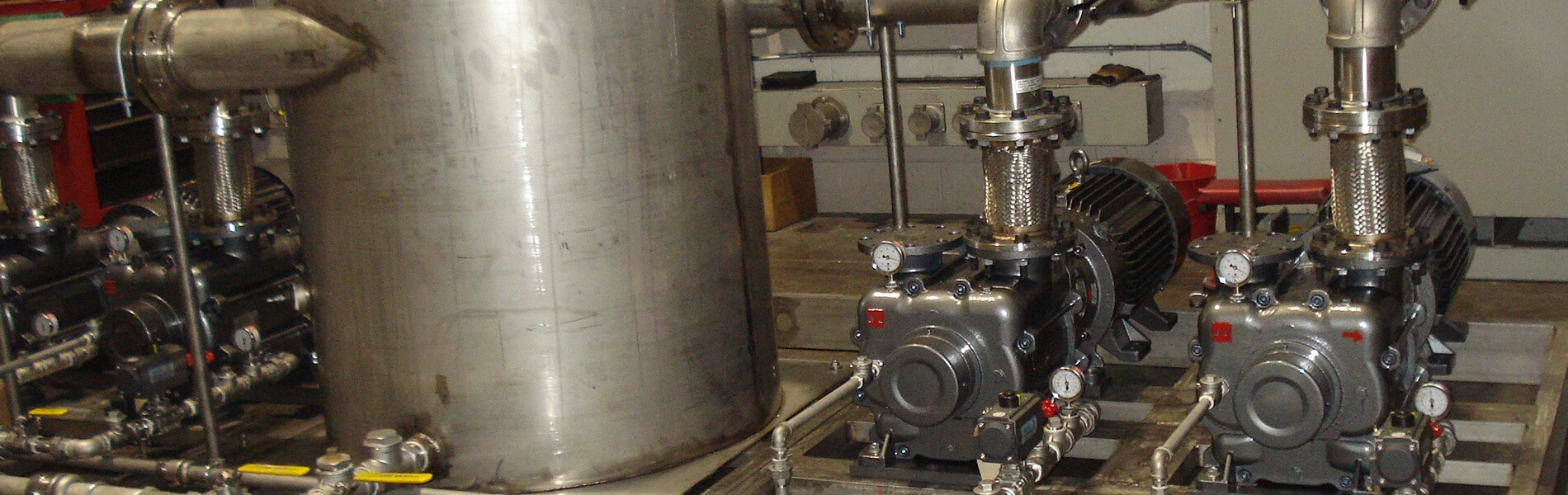

Custom Solutions DynaSeal™ systems can be provided in single or multiple system configurations with programmable controllers to meet your specific requirements. Explosion proof designs for those stringent environments. Wide range of materials including stainless steel, copper, etc.